About the client

Benefits

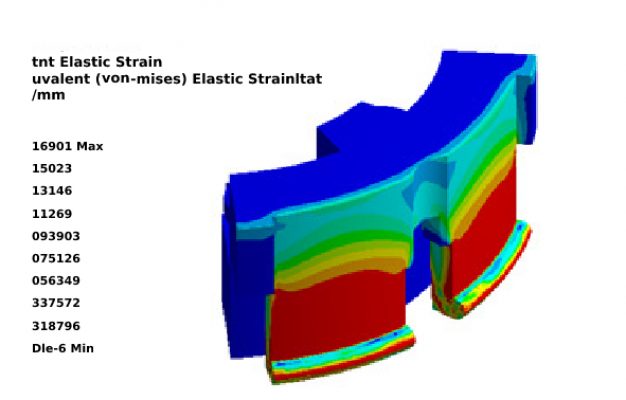

Sample analysis images (Cyclic symmetric Model)

About the client

Provide Innovative lighting technologies using LEDs that are more energy efficient, radiation free, Mercury free, eco friendly and having a long life compared to conventional lights. Lighting solutions are easy to install and maintain. Products ranges from Interior to Exteriors, Down Lights to Street Lights, Modern homes, Offices, Factories, landscape and many more. LED division is committed to supplying innovative, cost-effective solutions of superior quality LED in the shortest possible time. The products meet the highest quality standards and boast an extremely long service life and ensure continuous improvement in product and service quality, uncompromising quality management system is implemented in all fields of functions, from administration through to production and transportation.

Challenges

Initially wanted to setup a House-hold product in-house with minimal timeline. Planned to set up product lines with LED lighting solutions. Setting up for the Process design and design changes to the Product with edition features enhancing customer satisfaction as a primary goal.

Method adopted in innovating the product right from the conceptual level to design and development of the product lines has been the turnkey solutions for common man.

- EMI [Electro Magnetic Induction] issues were mitigated to a larger extent.

- Cost reduction with respect to competitor’s models to reach market value.

- Sourcing of bought out items.

Solutions

Provided with all necessary data to innovate the right product for ‘ Solar Portable Lighting Kit’, the required modifications during the product design lifecycle were carried with creative ideas from our design team. Proposed four options as concepts for the best choice.

Concept I: The product looked simple, with a self-weight of 10 Kgs and the housing was made from 4 piece model. This design was considered to be suitable for ease of assembly time.

Concept II: The second concept was freezed with reduced weight of 8 Kgs and the team proposed this considering the best design practices used in New Product Design (NPD) and Development. This design has less number of parts with rigid housing members along with result oriented functions with selected components.

The concept proposition were laid down with the final approval and accordingly produced with prototype orders to meet production requirements.

- Cut product cost by 15 %

- Increased level of confidence in designs

Key Features & Benefites

- Easy installation and ‘Do-It-Yourself’ kit.

- Remote controlled operation

- Ergonomic design for assembly.

- Power saving and Maintenance free

- Smart Phone charging

- Music with FM Radio & Mp3 playback

Solutions

Established in 2001, Total Outsource, Inc. (DGS) is ISO certified company offers Mechanical engineering services for Industrial, Semiconductor Material Handling, Energy, Oil & Gas, Restaurant & Food equipment, Transportation, Construction& Material handling and Packaging industries. Be it designing new products or solving complex engineering challenges, our multi-disciplinary team works closely with you to engineer solutions for a wide range of business requirements

Our specialized services are Product Design, Machine Design, Concept Design, CAD Customization, Design Automation, (3D modelling and 2D Drafting), Finite Element Analysis, Re-Engineering, Reverse Engineering, , Legacy conversion and Technical Publications such as Creating Operation/User manuals, Language Translation, 3D Graphics and Animation.