About the client

Challenges

- Made comparison chart between desired product and existing product, listed gaps in the existing design.

- Prepared design calculation sheet to re-size wheels, wheel shafts, worm gear and worm of gear box system, drive shafts for 4 positions of wheel assembly to place vessels of different size range.

- Re designed drive shaft to form a telescopic drive shaft

- Selected couplings, bearings to withstand axial and radial loads and electric motor.

- Changed contact angle between wheels and vessel to accommodate large vessels

- Replaced Pulleys with perpendicular gear box system for the speed reduction, which resulted in compact design.

- Concepts are made to place lead screw to move the wheel assembly from its one position to another position.

- All concepts were supported by the hand calculations to arrive at the proper sizing and effort required for the movement.

- Created parts, assembly and drawings of turning rolls in a CAD tool as per client requirement

- Conducted DFM, DFA and FEA on major sub-systems / aggregate level to validate designs and reduce costs

Key features & benefites

- 26% cost reduction of the turning roll assembly

- 50% of human efforts by standardizing most of the parts

- Supported in Supply chain activities as our subsidiary companies have Manufacturing facilities

About us

About the client

Our client is a leading manufacturer of manual, powered and robotic positioning systems and equipment in USA. Our client has provided innovative solutions to positioning requirements serving the welding, aerospace, aviation, automotive, transportation, ship building, material handling, thermal spray, and heavy equipment manufacturing industries. Our client manufacture equipment’s to afford customers many years of safe and dependable operation.

Challenges

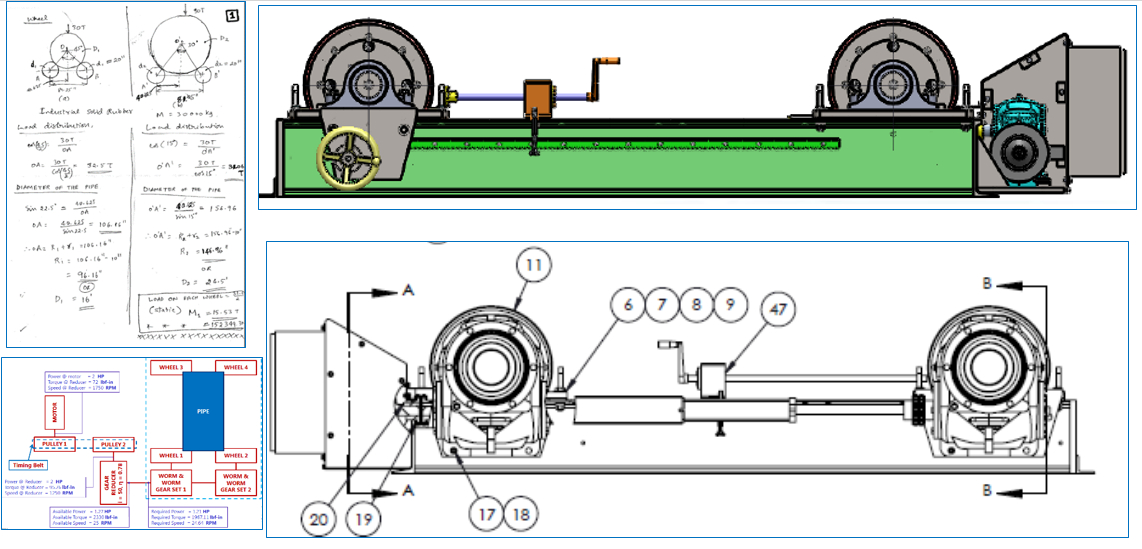

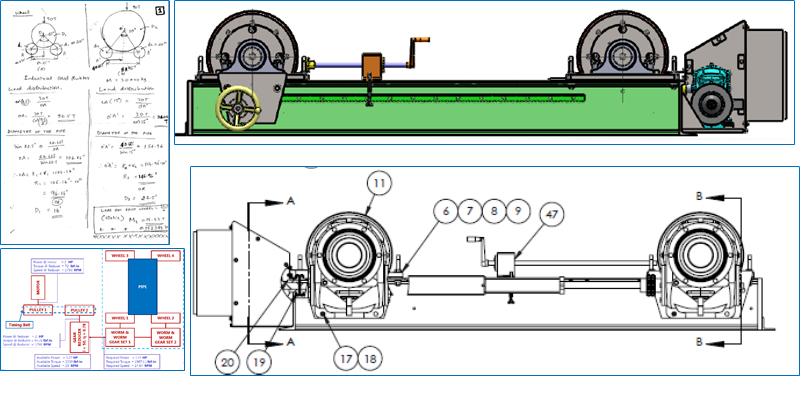

The client approached DGS seeking help in re-design of turning roll assembly to reduce the price of their existing products of having load capacity of 30, 60 and 90 ton

- Made comparison chart between desired product and existing product, listed gaps in the existing design.

- Prepared design calculation sheet to re-size wheels, wheel shafts, worm gear and worm of gear box system, drive shafts for 4 positions of wheel assembly to place vessels of different size range.

- Re designed drive shaft to form a telescopic drive shaft

- Selected couplings, bearings to withstand axial and radial loads and electric motor.

- Changed contact angle between wheels and vessel to accommodate large vessels

- Replaced Pulleys with perpendicular gear box system for the speed reduction, which resulted in compact design.

- Concepts are made to place lead screw to move the wheel assembly from its one position to another position.

- All concepts were supported by the hand calculations to arrive at the proper sizing and effort required for the movement.

- Created parts, assembly and drawings of turning rolls in a CAD tool as per client requirement

- Conducted DFM, DFA and FEA on major sub-systems / aggregate level to validate designs and reduce costs

Key Features & Benefites

- 26% cost reduction of the turning roll assembly

- 50% of human efforts by standardizing most of the parts

- Supported in Supply chain activities as our subsidiary companies have Manufacturing facilities

About Us

Established in 2001, Total Outsource, Inc. (DGS) is ISO certified company offers Mechanical engineering services for Industrial, Semiconductor, Material Handling, Energy, Oil & Gas, Restaurant & Food equipment, Transportation, Construction& Material handling and Packaging industries. Be it designing new products or solving complex engineering challenges, our multi-disciplinary team works closely with you to engineer solutions for a wide range of business requirements

Our specialized services are Product Design, Machine Design, Concept Design, CAD Customization, Design Automation, (3D modelling and 2D Drafting), Finite Element Analysis, Re-Engineering, Reverse Engineering, , Legacy conversion and Technical Publications such as Creating Operation/User manuals, Language Translation, 3D Graphics and Animation.